Our Hemp fabric begins life as an agricultural crop grown under license from the UK government Home Office on a farm in England. Using the Cannabis sativa strain, which contains only minute amounts of the psychoactive substance THC, the plants are sown from seed and reach over three yards in height in just 120 days.

Once grown, they are harvested, and the process of separating the stem’s fibers for spinning into yarn begins with dew retting – a natural way of allowing dew and rain to begin breaking down the tissues and pectins which surround the stem – which is then completed by mechanical decortication, during which the fine textile fibers are extracted from the heavier woody shiv. As Hemp is made using the long stem of the plant, the leaves are left behind to act as fertilizer, whilst the shiv is commonly used for building materials and animal bedding.

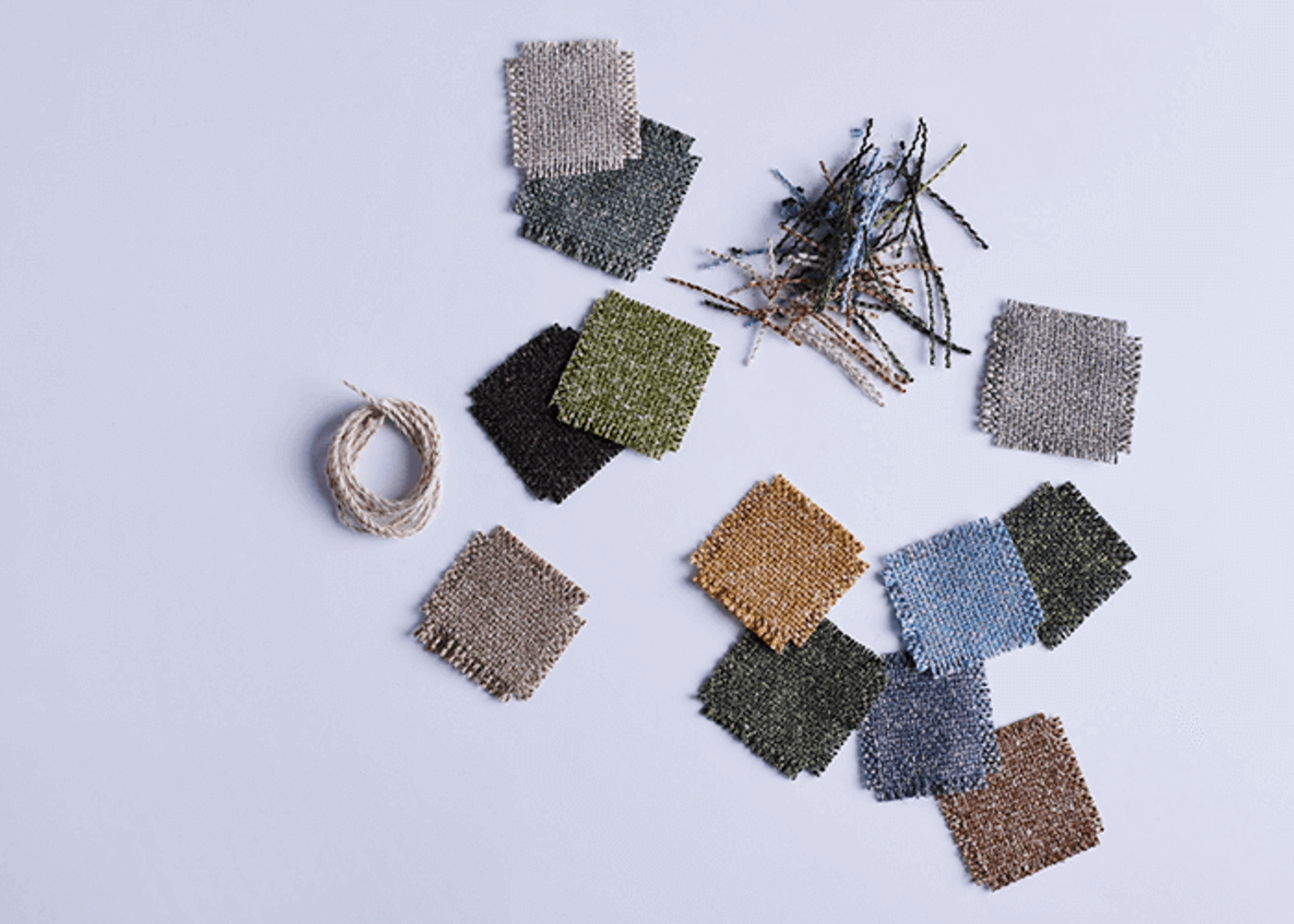

The hemp fibers are then blended with pure wool and spun together to create the yarn which is used to weave Hemp. When woven, the fabric is dyed into the 21 colorways which make up the range's palette, filled with organic tones which evoke its natural composition.